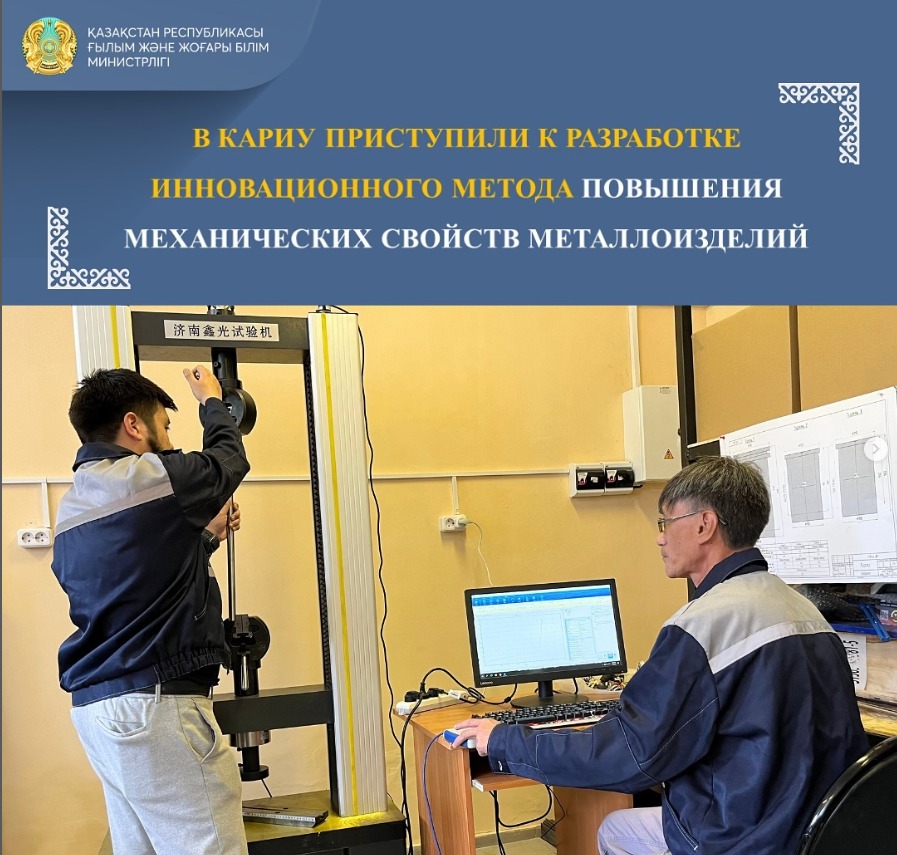

✔Scientists of Karaganda Industrial University are conducting research within the framework of the scientific and technical project "Development and research of a technological method for implementing intensive shear deformations during rolling in calibrated rolls", funded by a grant from the Science Committee of the Ministry of Science and Higher Education of the Republic of Kazakhstan.

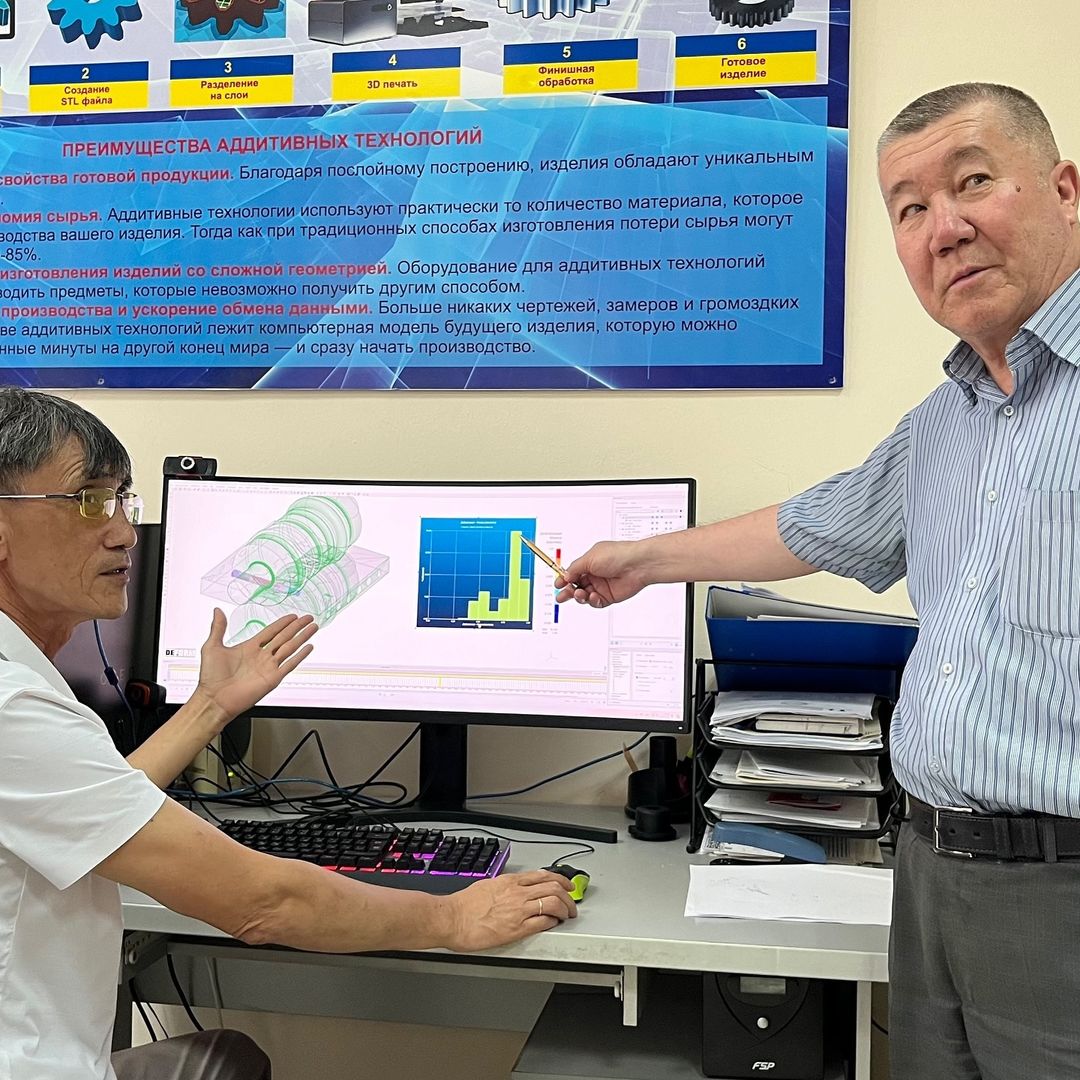

The head of the project, Candidate of Technical Sciences, Head of the Department of Technological Machines and Transport, Kairosh Nogaev, noted that the project proposes to develop new technological schemes for calibration of windings, ensuring the implementation of intense shear deformations.

The project proposes to develop new technological schemes for calibrating rolling rolls, ensuring the implementation of intense shear deformations. According to the hypothesis put forward in the project, the non-monotonic nature of the metal flow during rolling in the new gauge system will lead to deep compaction and elaboration of the metal structure at all levels of the metallophysical structure, which contributes to a comprehensive increase in the mechanical and service properties of metal products. The results obtained influence the development of theoretical and scientific foundations of technological methods for the implementation of intensive shear deformation in the field of longitudinal rolling and can be applied to substantiate a new technology for industrial production of rolled metal, in particular, they can be used to improve the technology of long-range rolling production of JSC "QARMET".