A unique laboratory has been created at the Department of Chemical Technology and Ecology of Karaganda Industrial University, which provides students with the opportunity not only to acquire the necessary knowledge, but also to develop their own startups. In this laboratory, students have already mastered the technology of manufacturing biologically active additives (dietary supplements), cosmetics, soaps and even confectionery products based on plant extracts.

The most promising developments are identified during an internal startup competition. For example, last year, two developments by novice pharmacists were among the best projects. As the head of the department Saule Kabieva explained, these ideas did not arise by chance.

"The first project was aimed at creating hair care products based on grape seed extract. The products include shampoos, balms and oils. The second project is the development of soap with various properties: invigorating, moisturizing and nourishing. The students conducted a marketing study, during which they found out that there are practically no cosmetics made in Kazakhstan on local shelves. At the same time, Kazakhstan is rich in plant raw materials, from which many useful biologically active substances can be obtained using the extraction method," Saule Kabieva said.

Currently, at the suggestion of Doctor of Medical Sciences, Professor Saule Zhautikova, a project for the production of dietary supplements based on selenium is being implemented in the laboratory. This trace element is important for the normal functioning of the immune and nervous systems, maintaining metabolism, the work of the visual organs, as well as the heart and blood vessels. Selenium has immunomodulatory, antiviral, anti-inflammatory and antioxidant properties, preventing cell destruction.

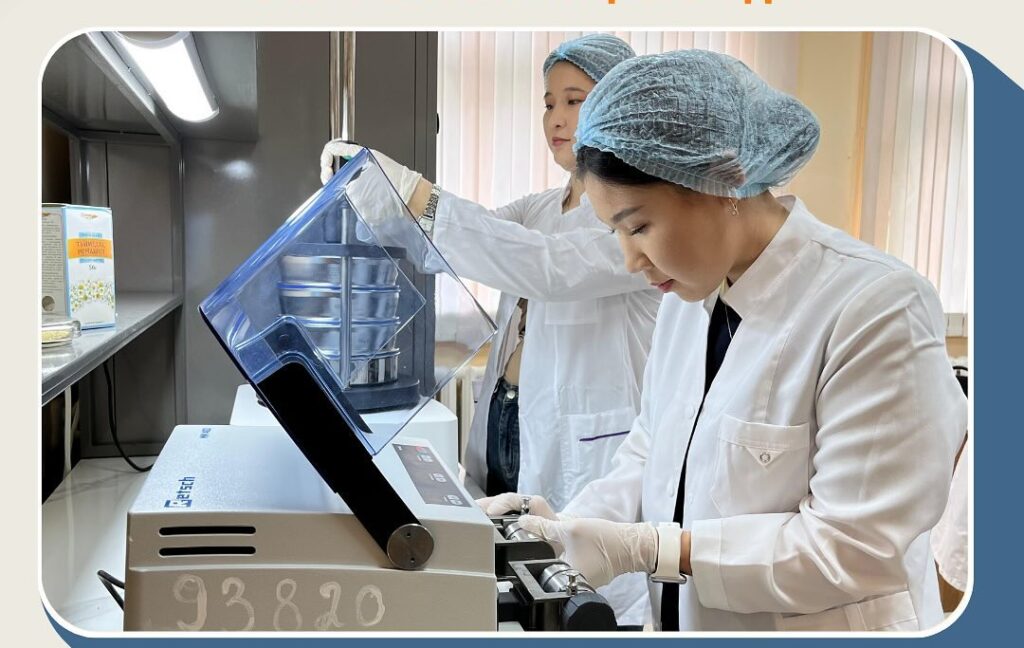

Recently, a 99.9% selenium production plant was opened in Balkhash, which allows it to be used in the laboratory for the development of dietary supplements. The professor explained: "We decided to use legumes to obtain dietary supplements. For a month and a half, we watered them with a solution of selenium salts. After that, the seedlings were crushed, and the content of a useful trace element in them was determined. The entire technological cycle can be carried out without leaving the laboratory. We also have a tableting press."

In addition, as part of the educational process, students are engaged in the manufacture of ointments, potions, sweets, oxygen cocktails, antibacterial films and healing patches. So far, the products are produced in small quantities, but the university plans to start mass production. The university hopes to attract the necessary funds for this through grant financing.