The Department of Technological Machines and Transport has a material and technical base (classroom fund, computer classes, laboratories, instrumentation, stock materials) that meets the current sanitary and technical standards and provides for all types of theoretical and practical training provided for by the curriculum, as well as effective implementation of research work.

The total area of the teaching and laboratory facilities of the department is 600 m2. These premises include: educational laboratories, teaching, classrooms, a computer class, a locksmith’s workshop.

In the laboratories of the department, operating stands are installed: hoisting and transport machines (bridge and console cranes; belt conveyor); crushing and screening equipment (jaw, cone, roller and hammer crushers, vibrating screen); technological machines (mixers, feeders, classifier; vibration platform); metallurgical equipment (converter, rolling stand); hydraulic drive; metal cutting machines, etc.

In 2020, a 3D engineering laboratory was created on the basis of the department, which is equipped with modern equipment and devices, such as a 3D printer, 3D scanner, laser and CNC milling machines. The main task of the new laboratory is to research and study advanced digital manufacturing technologies, such as 3D modeling, 3D printing, reverse engineering, technology design and CNC manufacturing.

CNC milling and engraving machine SH-6090

Purpose: cutting and milling, fine grinding of workpieces made of wood, plastic, plexiglass and soft metals (aluminum, copper, brass, etc.).

3D Printer PRISM SPECIAL

Purpose: printing high quality 3D parts from various types of thermoplastics.

CNC laser engraving machine REDSAIL X-700

Purpose: laser cutting and shallow engraving of various non-metal materials.

Turning and milling machine TFS-720

Purpose: performance of various turning operations, cutting of metric, modular, inch threads, milling and drilling of metal blanks.

3D scanner Shining 3D Einscan-Pro

Purpose: obtaining high-precision digitized models from objects.

Overhead crane laboratory bench with a lifting capacity of 250 kg

Purpose: research and study of the device and working processes of the overhead crane.

Belt conveyor laboratory bench

Purpose: research and study of the device and work processes of the belt conveyor.

Cantilever crane laboratory bench

Purpose: research and study of the device and work processes of the cantilever crane.

Laboratory installation “Vibrating feeder”

Purpose: research and study of the device and working processes of the vibratory feeder.

Laboratory installation “Jaw crusher”

Purpose: research and study of the structure and working processes of the jaw crusher.

Laboratory installation “Cone crusher”

Purpose: research and study of the device and working processes of the cone crusher.

Laboratory installation “Vibrating screen”

Purpose: research and study of the device and working processes of vibrating screens.

Laboratory installation “Classifier”

Purpose: research and study of the device and workflows of the classifier.

Laboratory installation “Swinging screen”

Purpose: research and study of the structure and working processes of the swinging screen.

Fuel injection engine bench

Purpose: study of the device and principles of operation of the injection engine control system.

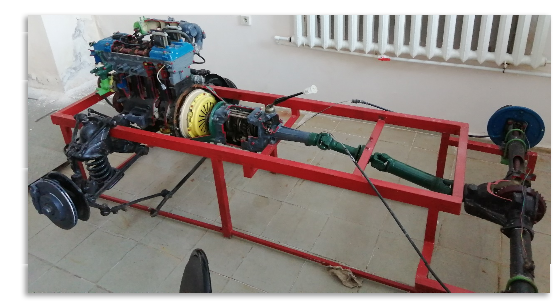

Bench of transport equipment based on the units of the GAZ-31 “Volga” car

Purpose: study of the device and principles of operation of transport equipment.